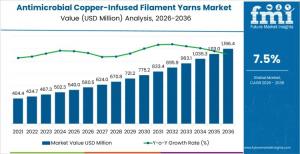

Antimicrobial Copper-Infused Filament Yarns Market to Reach USD 1,196.4 million by 2036, Driven by Healthcare

Market grows at 7.5% CAGR through 2036, fueled by demand in medical textiles, workwear, and hygiene fabrics requiring durable antimicrobial performance.

NEWARK, DE, UNITED STATES, January 20, 2026 /EINPresswire.com/ -- The antimicrobial copper-infused filament yarns market, valued at USD 580.5 million in 2026, is forecasted to nearly double to USD 1,196.4 million by 2036, exhibiting a compound annual growth rate (CAGR) of 7.5%, according to the latest market analysis. This growth is propelled by rising adoption across medical textiles, protective apparel, and hygiene-focused fabric applications where microbial control and durability remain critical performance criteria.

Request For Sample Report | Customize Report |purchase Full Report – https://www.futuremarketinsights.com/reports/sample/rep-gb-31586

Market Overview:

Antimicrobial copper-infused filament yarns represent a specialized segment of technical textiles engineered to deliver continuous antimicrobial protection by integrating copper particles directly into filament yarns. These yarns find critical use in healthcare uniforms, hospital linens, protective clothing, public transport seating, and bedding materials, especially where repeated laundering and extended use demand durable microbial efficacy.

The market’s expansion from USD 580.5 million in 2026 to an anticipated USD 1,196.4 million by 2036 is largely underpinned by enhanced infection control protocols globally, coupled with institutional procurement mandates emphasizing hygiene and durability. Leading growth regions include China (8.7% CAGR), Brazil (8.3%), and the USA (7.2%), reflecting the integration of antimicrobial yarns into large-scale healthcare, industrial, and consumer textile applications.

Material Science and Market Dynamics: How Copper Integration Shapes Demand

The market is segmented by copper integration techniques—copper-coated filaments (dominant with approximately 36% share), copper-embedded polymer yarns, copper-alloy filaments, and other proprietary methods. Copper-coated filaments are preferred for healthcare textiles due to their ability to maintain surface antimicrobial activity while preserving the mechanical properties of base polymers.

Material specification is a meticulous process governed by stringent regulatory and performance requirements. Efficacy retention after repeated wash cycles, skin safety, abrasion resistance, and color stability are pivotal benchmarks. Once a yarn system passes qualification and regulatory scrutiny, it becomes entrenched within approved textile platforms, limiting supplier turnover and emphasizing long-term partnerships.

Market Applications: Where Demand Concentrates

The healthcare and medical textile segment accounts for roughly 34% of demand, driven by hospital linen systems and protective apparel requiring verified antimicrobial efficacy through rigorous institutional laundering protocols. Workwear and public-contact textiles form another significant application, where abrasion, sweat exposure, and durability govern yarn performance. Additionally, home textiles, including bedding and mattress covers, leverage these yarns for odor control and hygiene.

Demand is largely driven by infection control standards and institutional procurement policies, notably in the United States and Brazil, where public health programs mandate antimicrobial textile use. Meanwhile, manufacturers in Japan and South Korea emphasize material governance and platform-based product strategies, ensuring consistent yarn performance across multiple product lines.

Market Challenges: What Limits Adoption

Despite growth prospects, market penetration is constrained by production cost premiums, complex copper dispersion requirements, and extensive qualification cycles. Copper incorporation affects polymer melt flow and filament tensile strength, necessitating controlled manufacturing processes to prevent performance degradation. Higher costs compared to untreated yarns challenge price-sensitive segments, while regulatory and requalification demands extend product launch timelines.

Competitive Landscape: Who Leads the Market

Key players shaping the market include Cupron, Noble Biomaterials, Unitika, Toray Industries, Teijin Frontier, Eastman, Wellman Advanced Materials, Toyobo, Coats Group, and Ascend Performance Materials. These companies compete through proprietary copper integration technologies, consistent antimicrobial performance validation, and compatibility with textile manufacturing processes.

Cupron leads with specialized copper complexes offering stable antimicrobial efficacy. Noble Biomaterials focuses on healthcare and high-contact applications, while Unitika and Toray Industries emphasize high-performance and industrial textiles. Suppliers maintain market share by ensuring reproducible quality, regulatory compliance, and technical support during fabric integration.

Regional Outlook: Growth Drivers by Geography

• China: Leads with an 8.7% CAGR, leveraging large-scale textile manufacturing and expanding antimicrobial applications in medical and consumer goods.

• Brazil: Growing at 8.3% CAGR, supported by institutional textile procurement linked to public health initiatives.

• USA: Growth at 7.2% CAGR driven by healthcare, performance clothing, and bedding applications aligned with infection control standards.

• South Korea and Japan: Mature markets with focused growth of 6.7% and 6.0% CAGR, respectively, emphasizing manufacturing governance, material consistency, and long product lifecycles.

Outlook and Industry Relevance

The antimicrobial copper-infused filament yarns market is expected to sustain strong growth through 2036 as infection prevention and hygiene standards intensify worldwide. Textile manufacturers and healthcare institutions increasingly prioritize materials that offer inherent microbial protection without added post-production treatments, facilitating safer environments in medical, public, and consumer spaces.

Commercial success in this market relies on early involvement in textile design, validated performance claims, and adherence to long qualification and reapproval cycles. Future innovations will likely focus on improving copper dispersion uniformity, reducing production costs, and broadening application ranges.

About the Report

This comprehensive market analysis covers quantitative metrics, copper integration methods, application segments, fiber types, and customer profiles across global regions including North America, Asia Pacific, Europe, Latin America, and Middle East & Africa. It leverages data from authoritative sources such as the World Health Organization, ISO standards, and the U.S. Environmental Protection Agency.

Browse Related Insights

Staples PP Nonwovens Market: https://www.futuremarketinsights.com/reports/staples-pp-nonwovens-market

Nonwoven Protective Clothing Market: https://www.futuremarketinsights.com/reports/nonwoven-protective-clothing-market

Hybrid Fabrics Market: https://www.futuremarketinsights.com/reports/hybrid-fabrics-market

Nonwoven Floor Covers Market: https://www.futuremarketinsights.com/reports/nonwoven-floor-covers-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.